As we bid farewell to another year, it’s time to reflect on the advancements that have reshaped the construction industry. In this annual roundup, we’ll explore the most innovative construction equipment releases of the year, showcasing the technologies, features, and improvements that are driving the industry forward.

1. Introduction: Embracing Innovation in Construction

The construction industry is no stranger to innovation, and each year brings new advancements that enhance efficiency, safety, and productivity on job sites. In this blog, we’ll highlight the top construction equipment innovations of the year, offering a glimpse into the cutting-edge technologies that are transforming the way we build.

2. Autonomous Construction Vehicles: Paving the Way for the Future

One of the standout innovations of the year is the integration of autonomous construction vehicles. From bulldozers to excavators, manufacturers are incorporating advanced artificial intelligence and sensors, allowing these machines to operate with increased precision and reduced human intervention. This not only enhances safety but also streamlines construction processes.

3. Telematics and IoT Integration: Smart Equipment for Smart Construction

The year witnessed a surge in construction equipment equipped with telematics and Internet of Things (IoT) capabilities. This integration enables real-time monitoring of equipment performance, location tracking, and predictive maintenance. Construction companies can now optimize their fleet management and minimize downtime through data-driven insights.

4. Electric-Powered Construction Equipment: Greening the Construction Site

Environmental sustainability took center stage with the introduction of electric-powered construction equipment. From excavators to cranes, the shift toward electric alternatives reduces emissions on job sites and aligns with the industry’s growing emphasis on eco-friendly practices. Battery technology advancements have extended equipment runtime, making electric options more viable for a wide range of applications.

5. Advanced Drone Technology for Site Surveys and Inspections

Drones continued to play a pivotal role in construction site management. The latest innovations in drone technology provide high-resolution imaging for accurate site surveys and inspections. Construction professionals can now efficiently monitor project progress, identify potential issues, and enhance overall project management through the use of aerial data.

6. Augmented Reality (AR) for Enhanced Operator Training

The incorporation of augmented reality in construction equipment training has been a game-changer. AR systems provide realistic, immersive training experiences for equipment operators. This not only accelerates the learning curve but also improves safety by allowing operators to familiarize themselves with equipment controls and operations in a virtual environment.

7. 3D Printing in Construction: Building the Future Layer by Layer

Innovations in 3D printing technology have expanded into the construction sector. Large-scale 3D printers are being used to create building components, reducing construction time and waste. This cost-effective and sustainable approach is gaining traction, with the potential to revolutionize how structures are built in the future.

8. Advanced Material Handling Systems for Increased Efficiency

Material handling is a critical aspect of construction, and this year saw advancements in systems designed to streamline the process. From automated conveyor systems to robotic material handlers, these innovations optimize logistics, reduce labor requirements, and improve overall project timelines.

9. Enhanced Safety Features: Prioritizing Worker Well-being

Safety remains a top priority in the construction industry, and this year’s equipment innovations reflect that commitment. Manufacturers have introduced enhanced safety features, including collision avoidance systems, proximity sensors, and automated emergency braking. These features contribute to a safer working environment for construction professionals.

10. Artificial Intelligence for Predictive Equipment Maintenance

Artificial intelligence (AI) has entered the realm of construction equipment maintenance. Predictive maintenance powered by AI algorithms enables equipment owners to anticipate potential issues before they occur, reducing downtime and minimizing the risk of costly repairs. This proactive approach to maintenance enhances the overall reliability of construction machinery.

11. Compact and Versatile Equipment Designs: Adaptable Solutions for Diverse Projects

Manufacturers have responded to the diverse needs of construction projects by introducing compact and versatile equipment designs. Compact excavators, loaders, and other machinery are engineered for agility and adaptability, allowing them to navigate tight spaces and perform a variety of tasks on job sites with limited space.

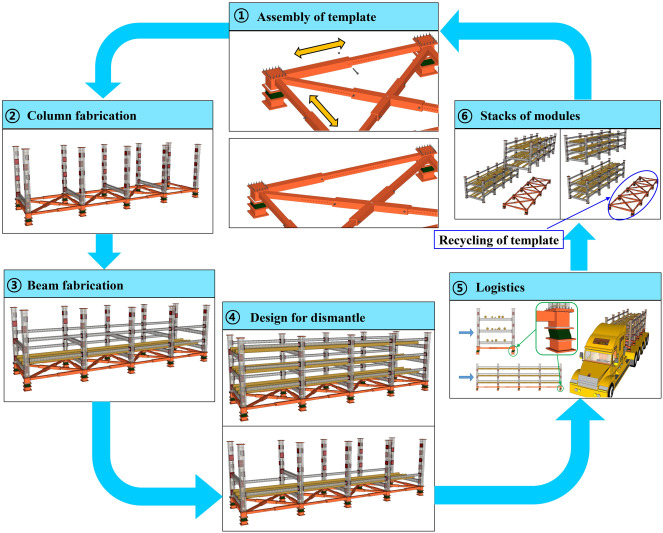

12. Modular Construction Equipment: Customizing for Unique Project Requirements

Modularity is a growing trend in construction equipment design. Modular components allow for greater customization to meet specific project requirements. Construction companies can easily adapt equipment configurations, enhancing efficiency and ensuring that machinery is optimized for the unique demands of each job.

13. Remote Operation Capabilities: Control at Your Fingertips

Remote operation capabilities have evolved, enabling operators to control equipment from a distance. This not only enhances safety in hazardous environments but also provides flexibility in managing multiple pieces of machinery simultaneously. Remote control technology is particularly valuable for tasks that require precision and accuracy.

14. Sustainable Materials in Equipment Manufacturing

Beyond the equipment itself, the industry saw a focus on sustainable materials in manufacturing. Manufacturers are incorporating recycled and eco-friendly materials into the construction of equipment, aligning with broader sustainability goals in the construction sector.

15. Conclusion: A Year of Innovation in Construction Equipment

In conclusion, the past year has been marked by remarkable innovation in construction equipment. From autonomous vehicles to sustainable materials, these advancements are reshaping the industry and setting the stage for a more efficient, sustainable, and technologically advanced future.

FAQs

1. How do autonomous construction vehicles enhance safety on job sites?

- Autonomous construction vehicles reduce the need for human operators in potentially hazardous situations, minimizing the risk of accidents and injuries.

2. What are the key benefits of using telematics in construction equipment?

- Telematics provide real-time monitoring, location tracking, and predictive maintenance insights, optimizing fleet management and reducing downtime.

3. How does 3D printing technology impact construction timelines?

- 3D printing in construction reduces construction time by creating building components with precision and efficiency, leading to faster project completion.

4. Why is operator training using augmented reality important in construction?

- Augmented reality enhances operator training by providing realistic, immersive experiences, accelerating the learning curve and improving overall safety.

5. How can artificial intelligence improve equipment maintenance in construction?

- Artificial intelligence enables predictive maintenance, allowing equipment owners to anticipate and address potential issues before they lead to downtime or costly repairs.